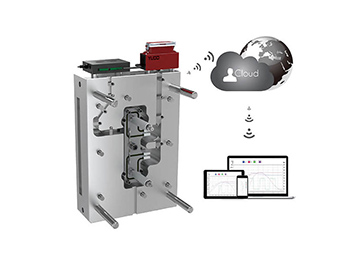

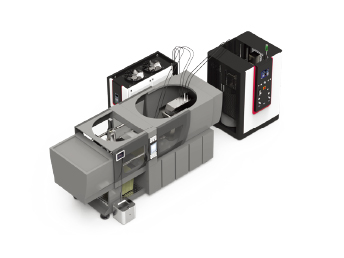

CW992

Features

- Interactive graphical user interface

- Multiple user options (timer, spm, vfc, shut off, i/o).

- Manage injection parameters and log files of each mold system.

- Internet-based central control.

- Automatic tool diagnostic;Power limit setting.

- Temperature data saving (USB).

High Performance

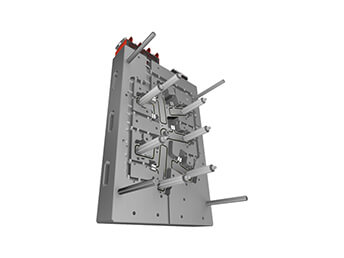

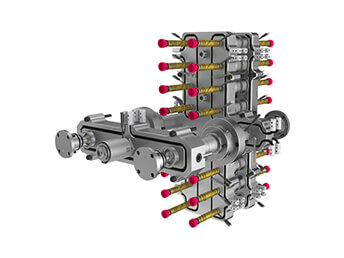

- Free choices of modular cards based on power and gates (5A / 6gates, 15A / 4gates, 30A / 2gates).

- PID regulator application(0.01s @ PAC).

- Adopted portable DIN standard cards.

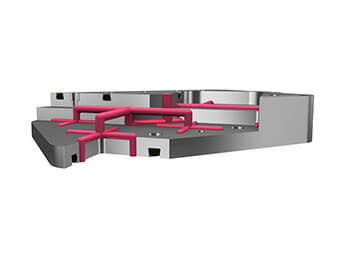

- “All-in-one”type insulation panel.

- Patented connectors designed for reliability.

- Indication of working state by LED(Output / Communication / Error).

- Fast current protection response(About 0.0001s).

- Heat-resistant material applied to prevent the components from overheating.

- Adaptive control of injection machine.

Options

- Sequence Injection Timer

- Max 16 Gates(A, B, C, B" Mode)

- LEDs indicate operation state(output/communication/error)

- VFC(Valve Feedback Controller)

- Precise valve gate control by SOL valve feedback

- SPM(Screw Position Meter)

- Max 16 Gates(A, B, C Mode).

- Shut Off Controller

- Various time control for ground/non-ground and low voltage heaters

- I/O Board

- Support In/Out lock function, Alarm , Indicator