Product Name: Wheel Housing1. The injection product is wheel housing, the plastic is PP, the weight is 1365g and the average wall thickness is 1.8mm.

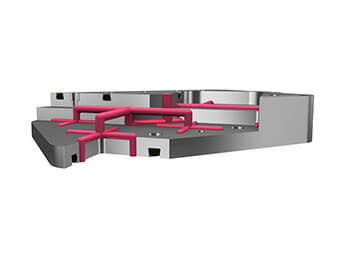

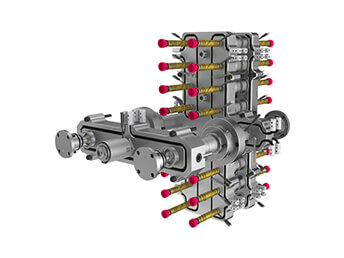

2. There're two cavities in the mold and the hot runner is a 18-drop pre-wired system, with 9 nozzles feeding on the left and right respectively on the product.

3. This system is another typical YUDO angled system, in which 6 nozzles are feeding on the product directly and the other 12 nozzles are feeding on the product from different angles through the adapter manifolds.

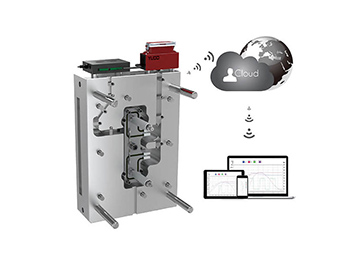

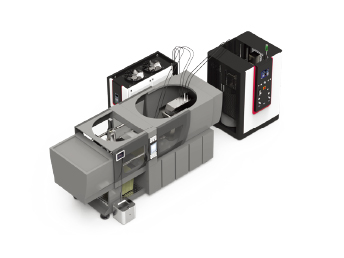

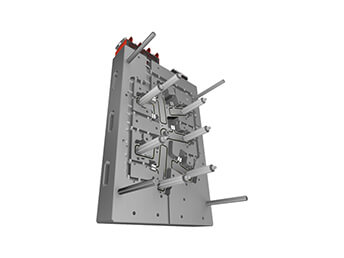

4. The parts and components of the pre-wired hot runner system are delivered after the internal assembly and testing of YUDO. This system is assembled into several modules respectively. Several modules are connected to form a complete system at the customer's site by using the YUDO patented anti plastic leakage docking technology. This installation is simple and fast, and can effectively prevent plastic leakage.

5. The sequential filling technology is adopted to realize the product filling balance and eliminate the welding line.