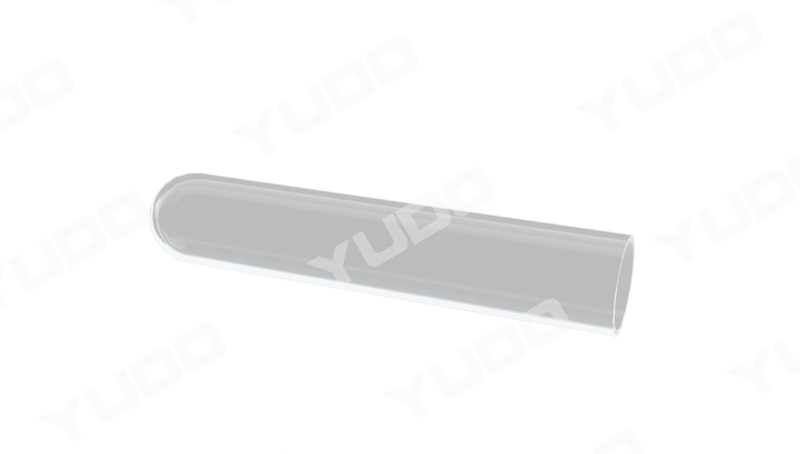

Product Name: Cosmetic Bottles

Resin: PCTG

Weight: 2.0g*16

Color: Transparent

Wall thickness: 1.6mm

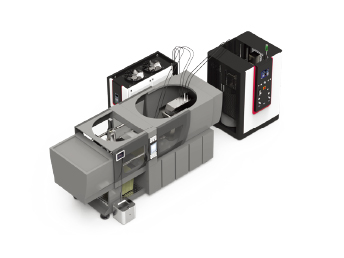

System Type: TINA MCH 10 VV

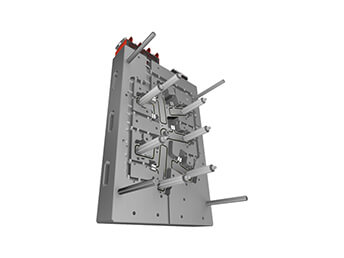

Nozzle Qty: 16

Cavity: 16

Project characteristics :

First: The project is a transparent plastic product. It requires to have balanced filling, while the appearance of the product cannot have obvious flow marks or streaks. In response to this requirement a copper tube heater is applied to the nozzle to make use of the heat uniformity of copper to ensure that the plastic at a uniform temperature at the best flow state and does not degrade.

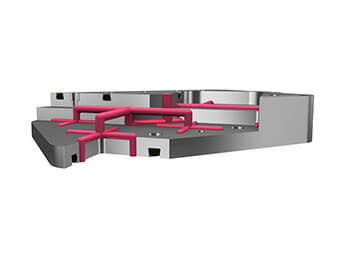

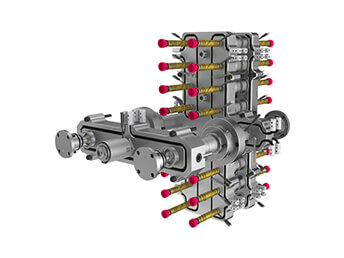

Second: Through the mold flow analysis we can accurately select the system flow channel size, and ensure the normal injection molding and injection molding pressure equilibrium.

Third: the manifold is made by ISO DIFFUSION BONDING. The valve pin guide bush (PGB) using a special structure design and the combination of the two items ensures that there is no dead zone inside the channel, reduce the resistance and wearing of the valve pin.