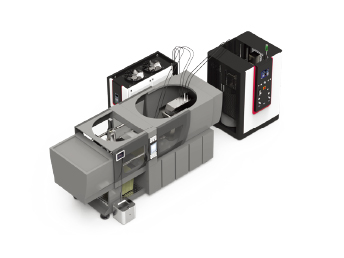

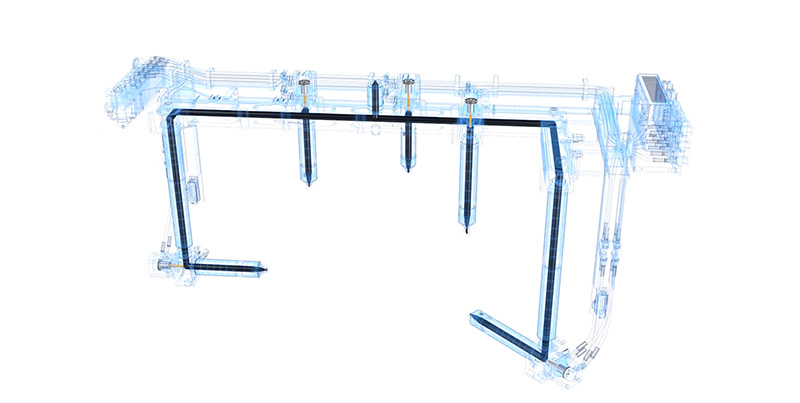

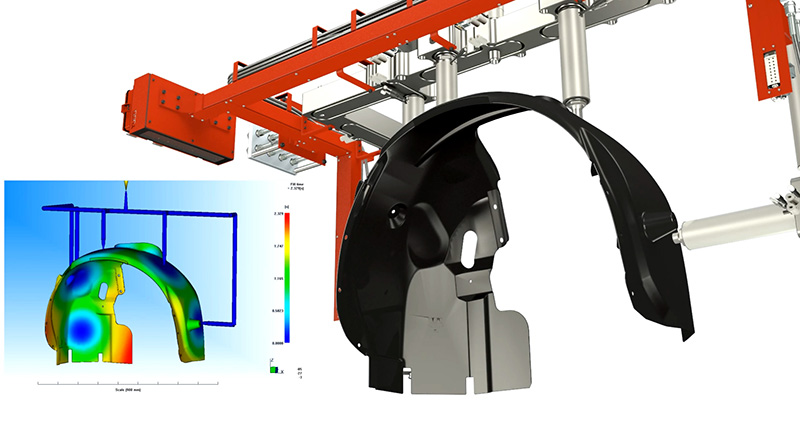

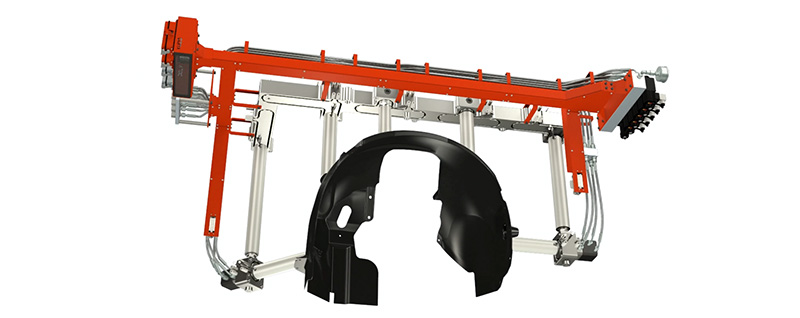

TINA_AM_Wheel

Arch

Material: PP

Part Weight: 1200g

Cavity Qty.: 1

Description:

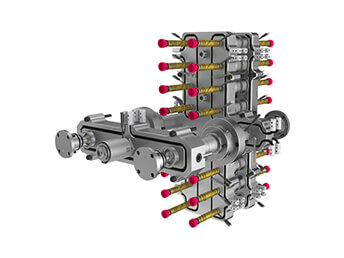

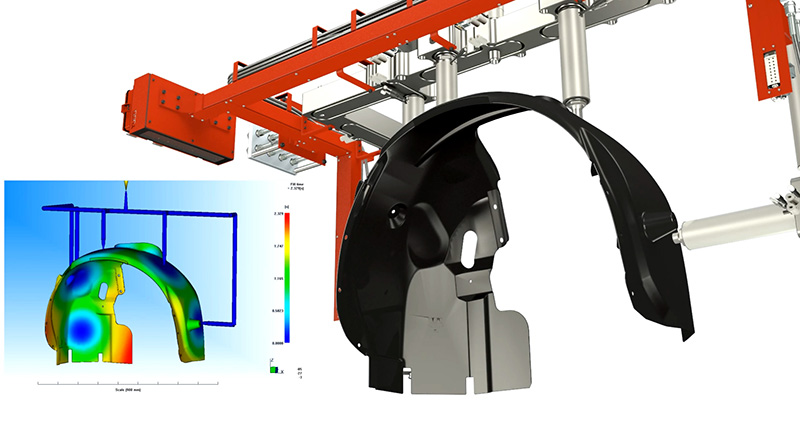

1. For YUDO TINA AM Angled system, the

special angled nozzles are able to inject directly on the part, thus solves the

problem of overlong flow length and over high injection pressure caused by the

connection of hot runner with cold runner in traditional mold design.

Meanwhile, YUDO TINA AM Angled system shortens the molding cycle, lowers the

labor cost and reduces the material waste, thus improves the work efficiency

greatly.

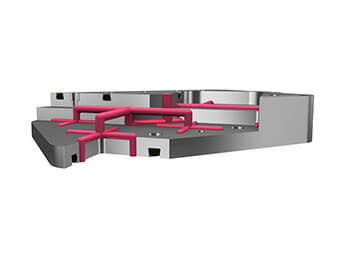

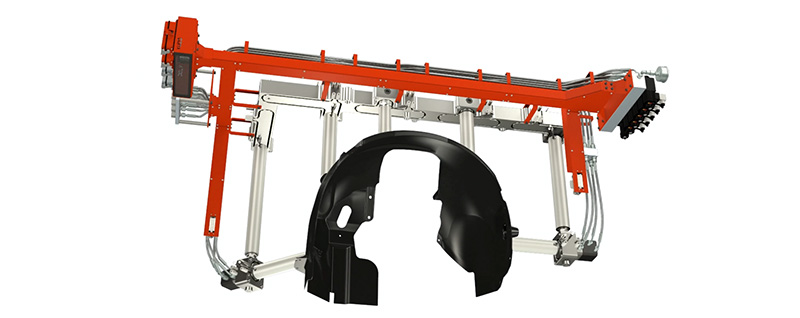

2. The structure of TINA AM Angled system

is improved by forming the angle with Nozzle-Manifold-Nozzle structure instead

of Angled Manifold-Nozzle structure, thus reduces the mold cutout, increases

the mold strength and simplifies the assembly.

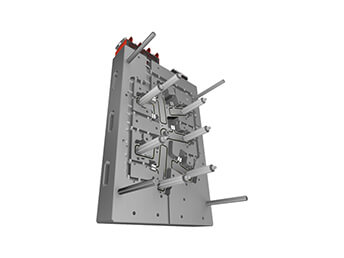

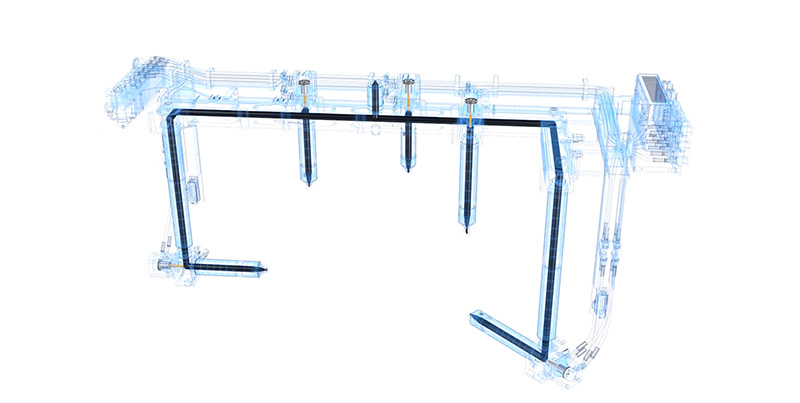

3. The gate structure of angled nozzle is

designed in the shape of the part to avoid making spurs, which is usually

applied in traditional hot runner system design, to reduce the manufacturing

procedure and improve the work efficiency.

4. Screwed-in type nozzle and manifold can

effectively prevent resin leakage problem caused by the precision error in mold

tooling.